Government Support Services

KRC is proud to partner with the Defense Logistics Agency (DLA) to deliver mission-critical Automated Operational Technology Support Services (AOTSS) for Automated Fuel Handling Equipment (AFHE) systems worldwide. This partnership leverages KRC's expertise in fuel handling automation to provide engineering, cybersecurity, and technical management services at multiple Defense Fuel Supply Points (DFSP) across the globe. With this contract, our team is enhancing the operational efficiency, environmental safety, and data security of AFHE systems, supporting DLA's commitment to reducing spill risks and achieving streamlined fuel transfer operations through robust, state-of-the-art technology solutions.

Our services encompass a full lifecycle approach—from design and installation to ongoing cybersecurity assessments and quality assurance. The project scope includes managing AFHE's Industrial Control System (ICS), providing field support, and ensuring compliance with the Risk Management Framework (RMF) to protect DLA’s critical infrastructure. By meeting stringent technical standards and deploying experienced, specialized personnel, KRC demonstrates its capability to deliver complex, scalable, and secure fuel-handling systems that align with the highest standards of defense and operational technology.

Examples of a few scopes of work are shown below

DFSP Manchester Support

KRC successfully partnered with the Defense Logistics Agency (DLA) to complete an Automated Fuel System Installation (AFSI) refresh at the Defense Fuel Support Point (DFSP) Manchester in Washington. This complex project required KRC to upgrade the existing Automated Fuel Handling Equipment (AFHE) system to enhance fuel transfer, storage, and automation capabilities. The AFSI refresh involved a comprehensive design-build request for proposal (RFP), detailed site assessments, and collaboration with design-build contractors, ensuring a seamless transition of the fuel depot’s infrastructure to an updated automated system. KRC’s team provided critical support during the design and bid phases, delivering over 500 pages of documents to facilitate contractor selection and ensure compliance with project specifications.

Throughout the project, KRC integrated new above-ground storage tanks (ASTs) while maintaining operational continuity with the legacy underground storage tanks (USTs). Our expertise in Supervisory Control and Data Acquisition (SCADA) and control system engineering enabled smooth integration of existing and new infrastructure, including installation of a redundant network backbone and updated software. This project underscores KRC’s commitment to delivering high-quality fuel automation solutions that meet the demanding requirements of military installations and help modernize critical fuel-handling facilities with state-of-the-art automation and control technology.

Conduct Site Survey

Facilitate Design Charette

Develop Conceptual Designs

Prepare Design Build RFP

Assist with Bid Evaluation

Assist with Contractor selection

Provide Construction Assistance

SCADA/AFHE Subject Matter Experts

Provide Independent Government Cost Estimate (ICGE)

Studies and analyses of DoD POL related existing facilities.

Key Tasks

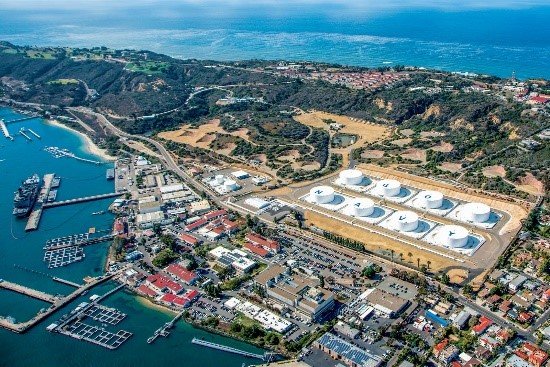

Point Loma Support

KRC was engaged by the Defense Logistics Agency (DLA) to perform a significant upgrade to the Automated Fuel Handling Equipment (AFHE) system at the Defense Fuel Support Point (DFSP) Point Loma in San Diego, California. This Automated Fuel System Installation (AFSI) refresh involved a meticulous design-build approach, with KRC conducting in-depth site assessments and developing a comprehensive RFP for the overhaul of the existing AFHE. A key challenge at Point Loma was the seamless integration of the facility’s Fuel Oil Recovery Facility (FORFAC), a complex system of valves, controls, and instrumentation, into the newly updated AFHE. This required precise coordination to ensure that all upgrades were completed without disrupting ongoing facility operations.

The AFSI refresh involved integrating new and existing components, including SCADA systems, programmable logic controllers (PLCs), control panels, and sensors, to ensure comprehensive fuel transfer, monitoring, and control capabilities. KRC provided design and construction assistance through every phase, from bid evaluations and contractor selection to on-site inspections and system handover. By successfully merging Point Loma’s legacy and updated systems, KRC demonstrated its capacity to modernize fuel-handling infrastructure while meeting DLA’s high standards for efficiency, safety, and operational continuity.

Conduct Site Survey

Facilitate Design Charette

Fuel Oil Recovery (FORFAC) Integration

Develop Conceptual Designs

Prepare Design Build RFP

Provide extensive coordination with intra governmental agencies

Assist with Bid Evaluation

Assist with Contractor selection

Provide Construction Assistance

SCADA/AFHE Subject Matter Experts

Provide Independent Government Cost Estimate (ICGE)

Studies and analyses of DoD POL related existing facilities.

Key Tasks

KRC recently completed a comprehensive API 570 Inspection Program at the United States Coast Guard Base in Kodiak, Alaska, supporting the integrity of the JP-5 and Diesel fuel piping systems crucial for the facility's refueling operations. Working as a subcontractor to BDS Architects, KRC reviewed and amended the existing inspection plan, conducting rigorous hydrostatic pressure tests and a Close Interval Potential Cathodic Protection Survey. Our team’s expertise in regulatory compliance and state-of-the-art inspection techniques ensures the system meets stringent API standards and the unique operational needs of USCG Base Kodiak’s fueling infrastructure.

Our inspection identified critical areas for maintenance, resulting in recommendations to enhance the long-term performance of the facility’s fuel piping systems. The project focused on safeguarding over 10,000 feet of fuel piping across varied terrains, from pier to bulk storage areas, utilizing advanced corrosion protection methods and visual inspections. KRC’s tailored approach and dedication to quality have positioned us as a trusted partner in managing the reliability and safety of high-stakes fuel transfer operations, reinforcing our commitment to engineering excellence in industrial and defense sectors.

USCG API 570 Inspections

Amended the 2015 API 570 Inspection Plan for updated compliance.

Conducted hydrostatic pressure tests to verify system integrity.

Performed a Close Interval Cathodic Protection Survey to assess corrosion.

Inspected 10,000 feet of piping for corrosion, damage, and wear.

Implemented monthly and annual visual inspections of piping.

Documented deficiencies and recommended repairs.

Enhanced interface coatings for exposed piping protection.

Updated maintenance schedules for testing and inspections.